Flooded Home? Can you Save the Cabinets?

How things are done series

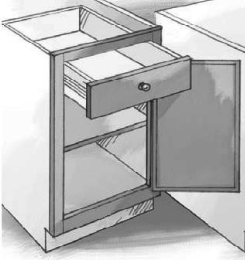

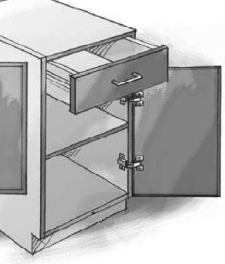

Kitchens flood, we count on it happening at least once in a kitchen’s life and we design so that a broken water line, fridge water line, or washer water hose doesn’t ruin all of the cabinets. The cabinets are set up on 4” tall feet so at most the toe kicks and end panels will take the brunt of the damage and they are easily replaced by design in our cabinets, not at all for face frame style cabinets where the doors are an integral part of the cabinet carcass.

We have had only one case to deal with, where a 3/8” copper prep sink water line broke loose after seven years. it sprayed two doors for hours till the customer woke up and was greeted with a half inch of water in the home. The wood floors were ruined and needed replaced but the cabinets cost a bit over $500.00 to put back in first class condition thanks to our construction methods.

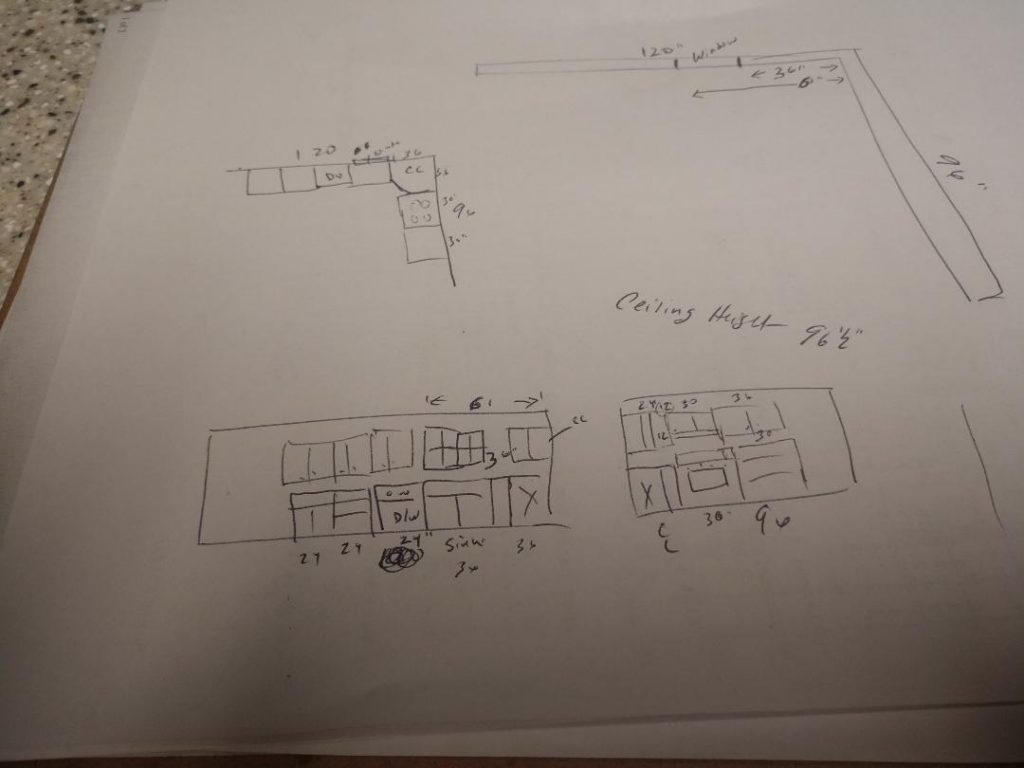

But with Oklahoma flooding in May of 2019, we need to talk about flood water damage versus clean tap water that is a half inch deep at most. When homes are built the studs are 92 5/8” tall and three layers of 2 x 4 plate are added, bottom plate, top plate, and an extra top plate to give the proper height. That puts the height of the actual wall or ceiling at 97.125” tall before the sheetrock goes on. Then you are down to 96 5/8” from floor to sheet rocked ceiling. Two 48” wide x 96” long sheet rock sheets are added leaving a 5/8” gap at the bottom and that saves your bacon.

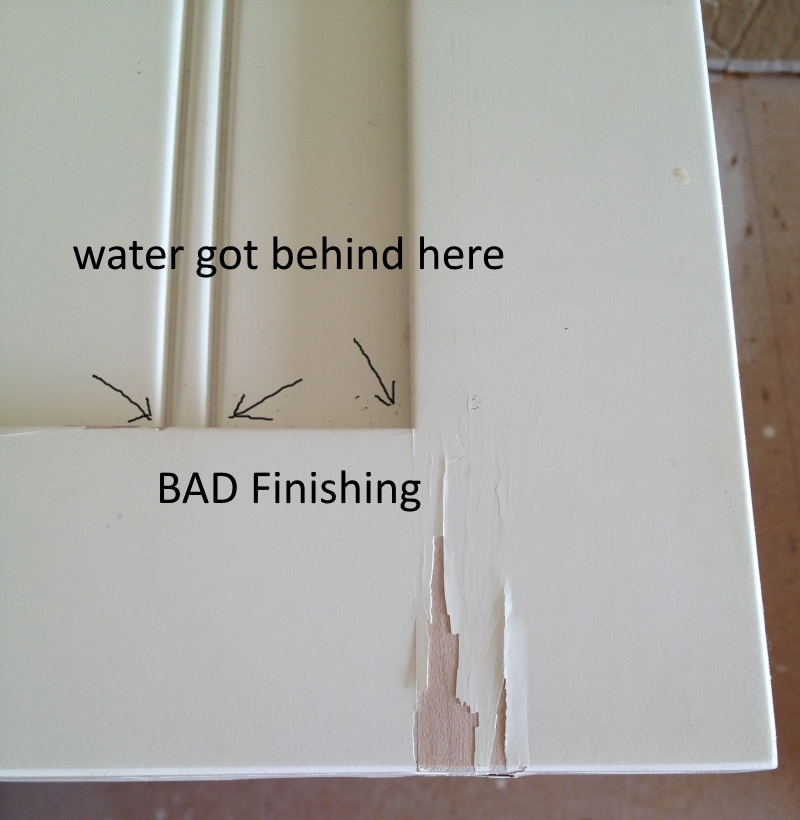

Flooded Cabinets Will Have Finish Problems Down the Road

- The wood will never be as dry as it was before after kiln drying

- Water will eventually escape and blister or flake the finish or cause blush

- Blush is a white looking semi transparent effect under the finish

- Floors and walls behind cabinets will mold if the old cabinets are not taken out

But in a flood all sorts of stuff is in storm water runoff. Animal excrement, human excrement, lots of mud, oil, and chemicals. And the water is high so it soaks into the sheetrock, is wicked up into the insulation and wood framing, leaving behind all of the contaminates when it does dry. Including fungus, bacteria, mold spores, and of course the mud and oil.

If you have a clean water flood you might be able to salvage the cabinets IF they were built up off the floor on nylon legs and you get the water out quickly. Particle board of course isn’t going to survive. First, empty your cabinets and remove as much excess water as possible inside the cabinet using towels or sponges. Pull the doors off and lay them around so both sides are exposed to the drier air, might not warp as much. Get fans going in the house and a good dehumidifier going if it is humid outside and close off the house so you can dry out the air inside the home quickly. A wood stove puts off lots of dry heat, not so much for a vent-less propane or natural gas space heater, water is formed with propane and natural gas is burned.

How things are done series

If you can find the original cabinetmaker some cabinets can be repaired and the ones damaged beyond repair can be replaced. The finish might need stripped and water stains removed using oxalic acid, then treat for mold using bleach and water. If you do not do this the cabinets will begin to stink. After the cabinets have dried thoroughly for several days refinish the cabinets.

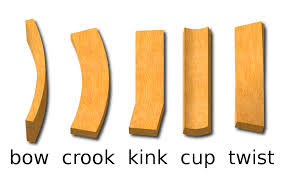

Now whether or not the cabinets will come through this process as good as new depends upon how much water and how long it soaked in and how quick you get the water out. Wood will never return to its kiln dried moisture content after being flooded. Water will cause finishing problems on down the line as the home heats up or the air dries out and the wood attempts to stabilize moisture content with the surrounding air. That causes finishes to flake off.

How about the Professional Restoration Companies?

They will have better fans and dehumidifiers but in the end they sell a service to insurance companies to try to limit the cost of a claim. The insurance company wants them to try to salvage the cabinets, even paying half of the cost of the ruined cabinets to clean them up and refinish will save the insurance company millions of dollars each year. And a year later when the finish flakes off it isn’t their problem. Even on the Edmond kitchen with little water damage, we did replace the doors that took the direct spray of water for six hours.

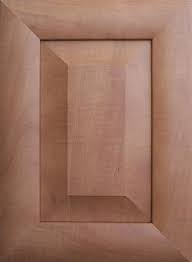

Repairing and Replacing Part of the Cabinets is Problematic

- Finding the original cabinet maker or one that has the tooling to match doors and cabinets is tough

- A stripped finish will stain out totally different than new wood on the replacement cabinets

- Bleach and water and oxalic acid and water adds more moisture to the already wet wood

- Insurance saves a lot, you get sub par cabinets with a portion of the lifetime use used up already

And have never had a call back saying anything bad happened with the kitchen. But sanding and striping those doors for re finishing, well, that would be ill advised given the cost of the new doors and finishing was close to the cost for slap dash work to save a few dollars for the insurance company.

If you Google flooded cabinets the restoration companies will talk about using wood glue to fix delaminated plywood and adding braces to strengthen weakened cabinets. Not good long term, you know that. And the floor and drywall behind the cabinets is likely to mold unless the cabinets are removed for drying the wall and even replacing the sheetrock. A month of drying and dehumidifying will help if you have the time.

But is it better to save the insurance company a few thousand dollars or you be made whole with cabinets that will return your home to its previous value?