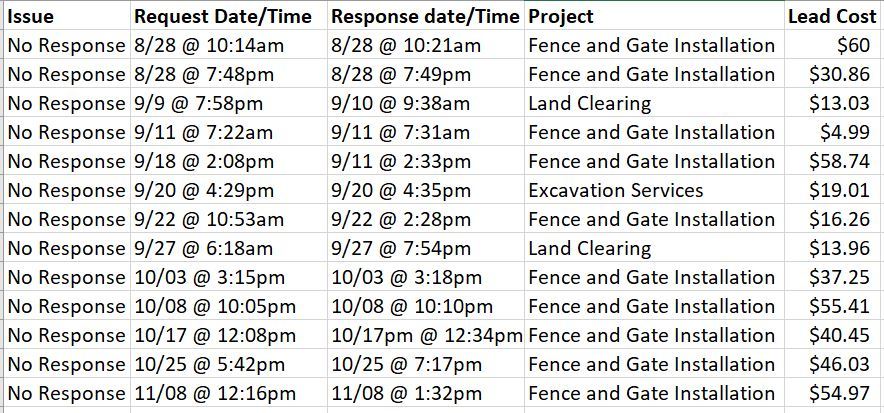

Skinny hanging strips on cheap cabinets

Skinny hanging strips on cheap cabinets

Suspension Blocks and Steel Hang Rail

Almost all of our competitors depend upon a skinny strip of scrap wood running along the top of the cabinet to hang the cabinet. As you can imagine, this isn’t the best way to hang a cabinet. I have seen homes with the slender wood strip still attached to the wall, with the rest of the cabinet laying on the floor in pieces.

.

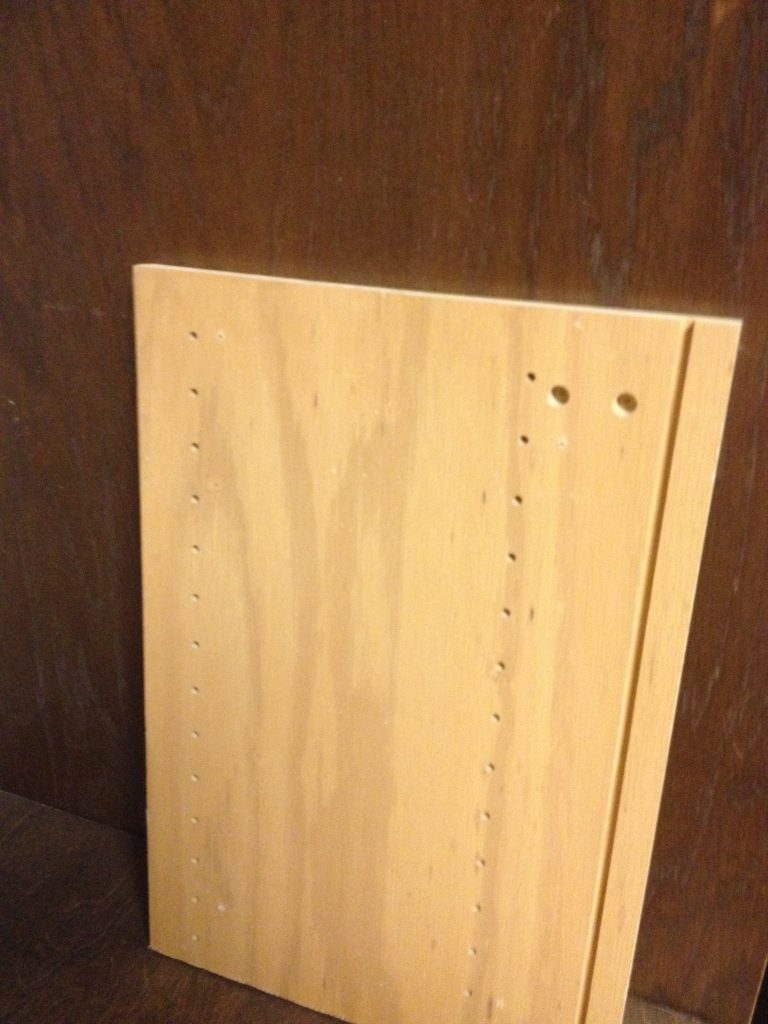

A better way is to use suspension blocks and a steel hanging rail, the suspension blocks have fittings that hammer into two 10 mm holes in the side of the cabinet. You are actually hanging the side of the cabinet which supports the rest of the cabinet. Then the steel hanging rail is screwed to the studs and large molly bolts used if the rail ends before the next stud. The suspension block protrudes past the back of the cabinet and hooks onto the steel hanging rail. Two screws handle any minor adjustments needed for the height and leveling of the cabinet..

In addition to having the cabinets hung much more strongly the rails makes installing and removal fast and secure. After the cabinets are leveled and lined up fasteners are installed so that the cabinet’s weight is spread all across the line of cabinets. After a wet spring or dry summer your

Oklahoma City’s Best Cabinetmaker

home might sink or the swelling soil might raise your home walls, with our cabinets removing the crown molding is easy and then the cabinets are unbolted and either adjusted back level or removed by pulling them p and out for repairs. d after unscrewing the cabinet from the others, you just lift it up and away for repair.

Using these suspension blocks and steel rail costs a quite bit more than using up table saw scrap but the end result is cabinets that are much easier to install and much more sturdy cabinets.

This is just one example of how we just do things better when we build cabinets.It is a lot cheaper to just make things right than come back later to fix the cabinets or lose a customer over poor quality work.

Oklahoma City’s Best Cabinetmaker and Countertop Shop