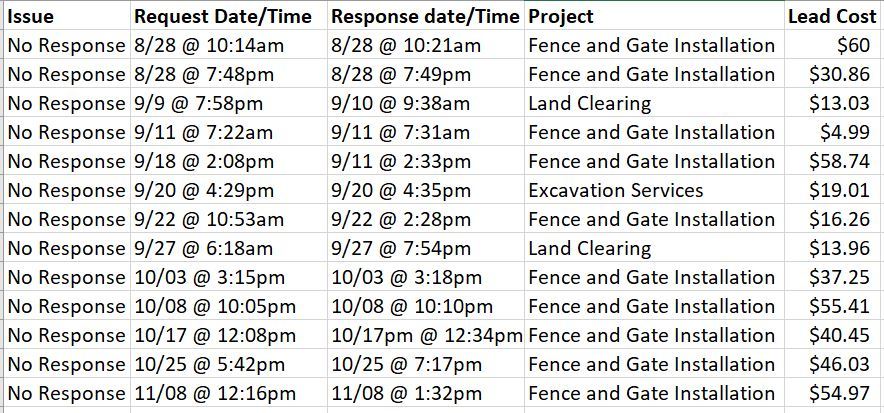

The supply shortages started hitting about this time last year, November 2021, and the price increases kicked in immediately. This wasn’t just the cabinet material industry, it was all over the building industry and just about every other industry as companies had downsized when Covid hit thinking the demand would not be there. What actually happened was that people were flush with government created cash, massive unemployment checks and stimulus checks and people splurged on electronics and online purchases and fixing up their home since they were spending more time at home.

When people went back to work in the summer of 2021 it was gradual, companies were living off inventory, not yet sure enough to restart production at pre Covid levels. When the inventory was used up, around the same time that massive pile ups were happening at the West Coast ports, availability of materials collapsed and prices quickly tripled. We had ordered 500 hinges in early February thinking we would build up our stock and didn’t get the American made hinges until August. Even at sky high prices you just had to wait.

Since around August the supply outlook has gotten better. MDF sheets and plywood is in stock, just at double the price it was a year before. Hardwood lumber stabilized and came down some to about 30% more than pre Covid prices. Hardware (drawer slides, hinges, misc cabinet fasteners/accessories) is still about double the cost it was pre Covid but you can get it now. New catalogs that have come out no longer have a retail price listed, a sign that the big companies believe that inflation is the new normal. We used to use those retail prices for five to ten years after the printing of the catalogs, prices were that stable that normal inflation just ate up a bit of the sale.

Looking ahead, the best experts are saying that the prices are due to three factors; demand, lack of production, and inflation. Demand has been sky high, the massive increases in shipping container costs and port delay costs have meant that companies have just said no to importing extra stock, plus the China Covid lock downs have shut off a lot of imports, and all the money that was created out of thin air by the government has made the dollar worth less domestically.

China is on the cusp of collapsing due to debt, unrest, the lack of a Covid vaccine that works, and the massive shipping costs have convinced a lot of supply chains to move out of China. But that will take time, to either re shore production back in the U.S. or a low wage country, and the duplication of the factories and supply chains are going to have to happen when there is a labor shortage and the cost of capital is skyrocketing.

My bank was offering interest of .5% last year, now they are offering 4% interest. The Federal Reserve has slammed on the brakes due to the wild inflation at the same time that millions of baby boomers have started to move their wealth from the stock market and mutual funds into safer bonds and annuities as they retire and can no longer risk the higher interest investments and seek safe and secure investments.

So the re building of American’s supply chains are going to occur in a period of tight money, high interest, inflated prices for materials and machines needed to build the new factories, and in a time of tight labor. Experts are saying we have five to six years of high inflation ahead of us unless we enter a severe recession or depression.

The time to remodel your house was last year when interest rates where cheap and credit was loose. But the inflation we are seeing isn’t going to moderate until around 2028 or 2029 so holding off might mean paying twice the price for a project since inflation is rising faster than interest rates. Now is the time unless you can hold off till we hit 2030 and bank on prices dropping. But when in our history have we ever seen prices falling across the board? Only once, the Great Depression and the government stepped in and instituted price and wage controls which lead to a twenty year depression. That won’t happen twice, 2030 prices are going to stick so the best time is now to invest in your home.