Cracked Mitered Doors

That Was a Stupid Idea….

There is always someone looking for a cheaper way to make things, and I said cheaper, not faster or better. Cope and stick doors have been around for hundreds of years with the original joints being hand made with hand tools.

We got faster thanks to the industrial age, motors and shaped steel cutters that hogged out the profiles much faster than a molding plane pushed by hand. But it is still time consuming to make a good joint.

And tear out, the bane of woodworking, the splintering of the back side of a board when cutting, routing, or shapering as the cutter comes to the end of the board on the edge of the board. Well, rails, the horizontal parts of a door, which are called the cope, are all edge grain so one edge usually splinters so you have the stick part that leaves a shaped perimeter around the inside edge of the perimeter of the door.

Ditto on the shaping of the edges of the doors. the trailing edge chips so you have an angle door edge to remove that chip and you have to pass the door back through the shaper on a large percentage of the doors to remove any end grain chipping.

Give me Your Checkbook Till We Leave the Store…

- Mitered doors sure are purty…..

- Picture frame joints

- Very deep profiles that are impossible using normal methods

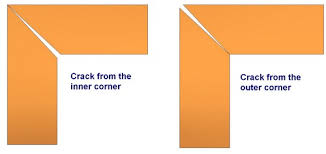

- They will crack at the joints and open up either on the toe or the heel of the joint as the humidity changes

So someone, a machinery maker no doubt wanting to sell new machines to replace the perfectly good old machines in the cabinet shops, came up with the idea of mitered doors. The rail and stile stock is all identical, cut at a 45% angle on miter machines that can do both cuts in one operation, with some sort of biscuit or loose tennon inserted to make a glue joint. Sometimes machined in place using CNC routers.

Then a minimum wage worker slaps some glue in the hole and clamps them up and shoots a pin nail in the joint and removes them to assemble the next door.

The problem is systemic, wood shrinks across the grain so anything you miter together will shrink and show a gap at the toe or the heel of the corner. That cracks the paint, shows an ugly gap, and of course the shrinkage breaks the glue joint leaving it just a matter of time before the doors fall off the cabinets.

At best it is just the majority of the door joints cracked and looking shabby. But hey, someone made some good money selling those doors to the homeowner and is it their fault the homeowner was uneducated? I say it is the shop’s fault but if you already invested in the equipment you gotta make it pay off. Cope and stick doors might crack on a few doors but they will not ever fall apart if property machined, properly glued, and clamped.

Tile Countertops

That Was a Stupid Idea….

I learned this one the hard way. Luckily it was my first “home”, a trailer house. Even then it got ripped out a few months later.

“But they have used tile for decades in the older homes.” Yup, with a 2″ thick concrete base, not glued on some plywood with mastic.

Tiles crack unless the base is thick and massive. Add to that the chipping and grout cleaning, well tile countertops do not age gracefully

The edges fall off when bumped, they always look dirty and the grout flakes out plus you don’t want to think about the amount of bacteria hiding in that grout.

But it is Cheaper..

- True, the first time you put it in

- Not so cheap when you have to replace it

- Yup, you can put hot pots on it, the one grace it has

- Going to devalue your home when you go to sell

A tile top could be made for a few hundred in materials but if you hire the job done you will spend $500 at a minimum and more likely $1000.00. That will make a good sized payment on a solid surface top that will last the life of the home or until you are sick of looking at the kitchen. Or you can purchase a laminate top for that kind of money.

Tile on the backsplash works, up out of the way, no one cutting or pounding on it to break up the grout. Away from most stain other than some spattered grease and oil, so seal several times a year.

Glue surface areas are like beams in engineering terms, half the depth or surface area, four times less holding power or strength. Coupled with the angle of the annual rings and you can have some warped top rails that move so much that the elastic qualities of the glue fail and the glue joint fails.