Quartz

Better than Granite but not a great material

Quartz countertop material was oversold from the start. Salesmen would come into the shop claiming scratch resistance, wouldn’t stain, and heat proof. About a year later the ads started appearing in Kitchen and Bath trade journals saying otherwise as the warranty claims were mounting.

Quartz countertops are not UV stable, no polyester resin truly is unless they spend a fortune on added chemicals, so sunlight, even what little UV light that comes from florescent bulbs will bleach or yellow the countertop. Quartz scrap left out side will quickly degrade from direct sunlight, bleaching and cracking the surface.

Quartz countertop materials also reacts to solvents like acetone which will etch the polyester resins, leaving streaks, spots, or dull areas.

Why not quartz?

- About half of the time quartz countertops will stain quite easily, which half is anyone’s guess

- Heat will ruin it quickly

- Seams are not guaranteed, they will break eventually

- Quartz popping, scratches, not repairable

- Etches easily with common chemicals, turmeric, coffee, red wine, even hard water will leave spots and glass rings

The product will etch easily too with acidic foods such as coffee, soy sauce, red wine, or ketchup and other tomato products being the top offenders. Any sort of metal can can leave rust stains, even hard water is notorious for leaving spots and streaks or rings around the faucet components. Rechargeable battery chargers will put off fumes that will etch quartz countertop back splashes and the quartz countertop beneath the plug in charger

Quartz is a mixture of polyester solid surface and quartz chips, around 7% polyester by weight, between 28% and 35% polyester by volume which they forget to mention in their marketing. Any mixed product like this must have some thought put into it, especially on the co-efficient of expansion of the two products which is the rate of expansion and the reason for the expansion to prevent the product from ripping itself apart as the temperature changes.

An example of a combination that works is reinforced concrete, concrete and rebar have the same co-efficient of expansion

Quartz expands more and faster than polyester which is why that quartz top on the top of the page had a big quartz chunk pop out. Good fabricators will warn you to never drag anything across a quartz countertop, especially a metal pan, not because the metal will scratch it but because the likelihood of a loose quartz chip popping out being under the pot and causing a scratch.

Very low temperature changes such as when buffing an area of a quartz top or even friction from the tie down straps used to hold a top being transported can and have left marks that can’t be removed. Online forums have a number of consumers that have had to have their tops ripped out and replaced over markings on the top caused by low level heat, attempts to polish, or attempts to fix a dull spot or scratch. One company has claimed to have developed a paste or cream for top polishing quartz countertops but the reviews are mixed as some colors can be polished by an experienced technician but you are rolling the dice if you try.

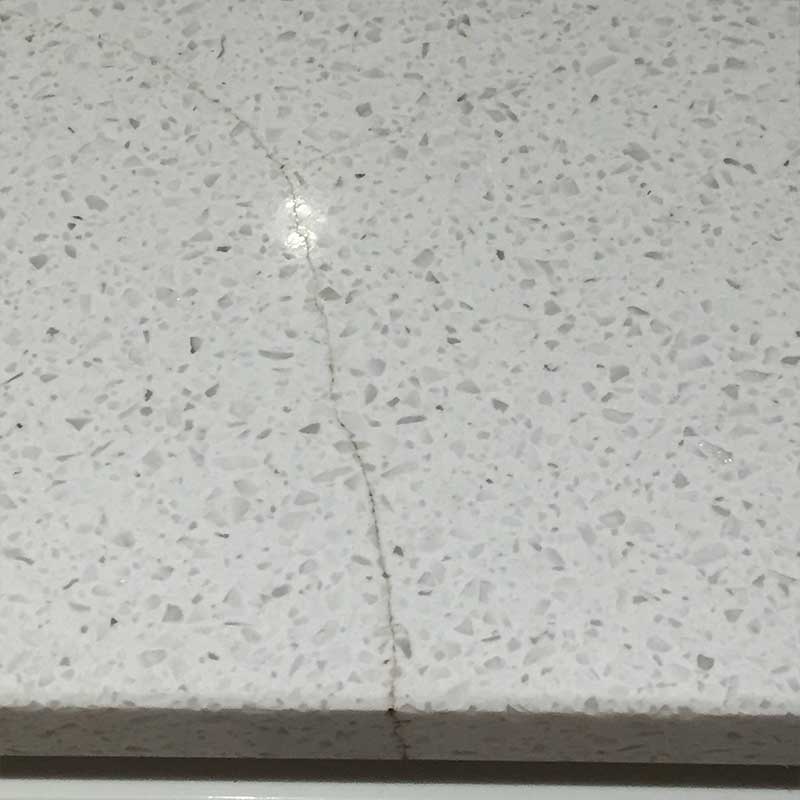

The difference in co-efficient of expansion is also the reason that quartz countertop seams are not covered under their warranty. As the two materials expand at different rates the glued joint will rip itself apart. A house in Nichols Hills that we redid a few years back had had new quartz countertops installed throughout the home about four years earlier and every single seam had broken.

Quartz countertops scratches and damage is not repairable because the super hard quartz chips and the soft polyester don’t polish at the same rate and the minor heating caused by the polishing changes the color of the polyester. This is well known and understood in solid surface work, if you are going to heat and bend part of a job you need to heat all of the parts that are seamed to the heat formed part because the heating will change the color slightly.

Polishing quartz countertop edges is okay because all of the edge gets polished and there is a break between the polished edge and the top of the countertop. While you are polishing you are rotating the water fed diamond pad grinder up and down across the edge but if you go too far on a single pass of the grinder and get up on the top you have ruined the countertop and must start over with a new slab of material.

An example of a combination that works is reinforced concrete, concrete and rebar have the same co-efficient of expansion

Quartz expands more and faster than polyester which is why that quartz top on the top of the page had a big quartz chunk pop out. Good fabricators will warn you to never drag anything across a quartz countertop, especially a metal pan, not because the metal will scratch it but because the likelihood of a loose quartz chip popping out being under the pot and causing a scratch.

Very low temperature changes such as when buffing an area of a quartz top or even friction from the tie down straps used to hold a top being transported can and have left marks that can’t be removed. Online forums have a number of consumers that have had to have their tops ripped out and replaced over markings on the top caused by low level heat, attempts to polish, or attempts to fix a dull spot or scratch. One company has claimed to have developed a paste or cream for top polishing quartz countertops but the reviews are mixed as some colors can be polished by an experienced technician but you are rolling the dice if you try.

Quartz countertop material is also notorious for cracking and warping due to internal stresses. The sheet is poured and cured then ground down and polished at the factory. Once you cut that large slab down into parts for smaller countertops you redistribute the internal stresses caused by the curing and polishing.