Features of Old World Cabinetry

- Staggered height and depths

- Ornate carvings and embossings

- Distressed finishes

- Mullioned doors with antiqued glass patterns

- The goal is to mimic the old manor house cabinets in Europe that were added to over generations of households, with subtle differences in additions

The Coe Kitchen

This Oklahoma City kitchen was featured on the cover of a national countertop industry magazine and a long running TV ad campaign we did back in the early 2000’s and was made of painted red oak. Six rooms were gutted, walls removed, leaving a huge space for a huge kitchen and dining room. The picture above shows the ornate arched vent hood, pot filler mounted above the stove, and mullion doors on the china cabinet on the left side of the picture.

The lady of the home had a huge collection of ceramic pottery and china that was stored in two separate china cabinets and one open display area. At the request of the homeowner, and against our advice, a small chest freezer was buried under the countertop to the left of the fridge with a lift up lid concealed in the countertop. As we had warned the freezer burned out about a year after it was installed so we went back later and installed pullouts behind the cabinet doors that hid the front of the chest freezer.

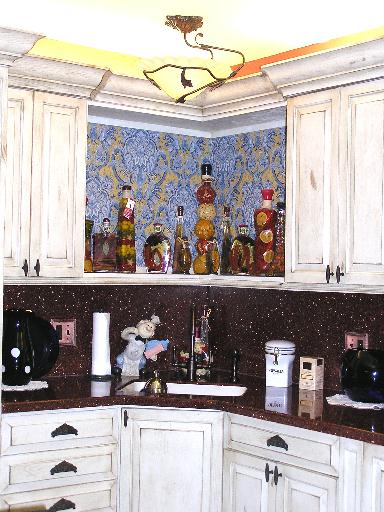

A Covel Road Kitchen

Heavy distressing, heavy glaze

- Raised panel doors, shapered drawer fronts

- Arched valances and corbels

- Staggered depths

- Mullioned doors

- A set of cabinets that will never look common thanks to the use of the distressed finish, offset by dazzling high gloss polyester countertops and stainless steel appliances.

Heavy distressing, heavy glaze

This set went out in NE Edmond into a gated community, an oil executive’s family. Raised panel doors, shapered edge drawer fronts, stacked upper cabinets with lighted mullion pane doors. Arches and corbels over the kitchen window and the dish rack. Two open display areas plus the bookcase end on the distressed brown painted island.

The home had a custom made prefabbed foundation but it was installed out of level and no one told the home owner until we showed him that the entire kitchen floor was two inches out of level from one end to the other, around 16 to 18 feet.

The furniture toe kick had to be remade in the lower sections because of the massive out of level condition but it hid the problem fairly well as few people are looking at the toe kick to see if it is wider on one end. Certainly cheaper than tearing down a two story house to fix the out of level bottom floor.

We did the cabinets in the entire house, two floors and a basement laundry.

The brown painted island is a simple sand through distressed finish. Stain for the sand through, apply pre cat sealer, paint the brown lacquer coat, sand through and re seal with pre cat sealer, then glaze and top coat with pre cat lacquer.

The island cook top lower doors are neat, we recessed an area to keep the doors and knobs away from the cook’s knees, using an arched top rail and arched raised panel doors to complete the look.

The stacked display cabinets with glass doors add quite a bit to a kitchen quote as you are building twice as many cabinets and using about one third more materials.

Save tens of thousands if you are looking at Habersham cabinets

.

Habersham kitchens are $100,000 plus

- Raised panel doors with applied molding

- 6″ crown accented with 3.25″ standard and egg and dart carved crown to achieve that multi generational look of a European or English manor house

- Staggered depths and heights, over nine feet tall

- Full wine rack and doweled dish rack

- Glass doors and even glass end panels on display area, full set of Rev A Shelf organizers, over $3,000.00 of organizers in this one cabinet set.

- Grass Nova Pro undermount, soft close, metal side drawer slide system.

- Fully accessible clam shell appliance garage, both sides swing open

Habersham cabinets are sold in major furniture stores and are known for their high end finishes. The cabinets, they aren’t really very good, fairly crude actually. Small local shops produce the cabinetry and Habersham does the finishing. Mathis Brothers had a Habersham kitchen, a small galley style, over $100,000.00 plus installation. You can get the same look and twice the quality for half the price.

A Habersham Look at a Fraction of the Price, One of our Showroom Kitchens

This set is in our showroom, built for a display at a home and garden show, and it is packed with Rev A Shelf organizers.

.

The curved top sections on the amoire flanking cabinets are a bear to make and quite expensive to produce but few shops in Oklahoma are capable of producing curved work.

The doors have applied molding around the inside of the stiles and rails. Very time consuming, around $1,000.00 per kitchen depending on size.

.

The island and separate amoire are painted turquoise, a color one would think would look awful, but under the dark glaze and pre cat finish it looks amazing. The drawers in the entire set are Grass Nova Pro, an undermount system with high quality metal sides, soft close of course. Cabinets like these will cost over $1,000.00 per linear foot but that is a third of what Habersham sells and less than some Kraftmade cabinets from Home Depot. These are better cabinets and a better finish and won’t take a year to arrive to be installed.

.

The curved top sections on the amoire flanking cabinets are a bear to make and quite expensive to produce but few shops in Oklahoma are capable of producing curved work.The doors have applied molding around the inside of the stiles and rails. Very time consuming, around $1,000.00 per kitchen depending on size.

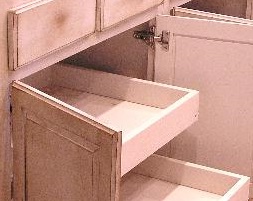

Full pullouts, adjustable in height, are enclosed under the top drawers. One upper corner cabinet is a L shaped piano hinge style fold out door, the other is a dubbed shape with a tall lazy Susan. The pantry has fold out piano hinged shelves. When you get into these fancy pantries they are expensive due to the time to get everything designed and fitted. The commercial models are over $1000 and then some. Gotta have deep pockets for this kind of storage solutions so make sure you have to go this route, might be cheaper just to add cabinet length to the job and get more storage at less money.

.

The finish required to match Habersham’s finish isn’t cheap, count on a minimum of $5,000.00 for a medium sized kitchen as it will take twice as long to finish than it takes to build the cabinets. As it is maple you have to distress heavily and score with 80 grit sandpaper to get the glaze some texture to catch in. Then a coat of glaze is hand painted on, allowed to dry for several days, and sanded off.

It takes a case of sanding sponges to do one kitchen and about four days of work for a medium kitchen just for the glazing process. But the look is amazing as it is impossible using other methods to get this much glaze to remain without interfering with the adhesion of the final pre cat top coat.

.A lot of kitchens like this rarely get used. Most of the trophy kitchens in Nichols Hills are just for show and a small butler’s pantry is hidden somewhere nearby that is used for the day to day cooking and the expensive kitchen is used for parties and just because the prices of the homes demand a big old honking expensive kitchen.

Cabinets for a house with a $10,000 sink

- Massive 30″ tall corbels on island raised bar top

- Mullion doors on stacker cabinets, nearly 10′ tall

- Staggered depths and height cabinets

- All fridge and dishwasher have paneled fronts

- Designed in conjunction with an area interior designer for a very wealthy class action lawyer

- Intricate fireplace surround and flanking bookcase set with arched top cabinets, not just curved top, but an eyebrow arch behind the eyebrow arch mullion doors

- Very few organizers used as this kitchen had more storage than two cooks could fill up

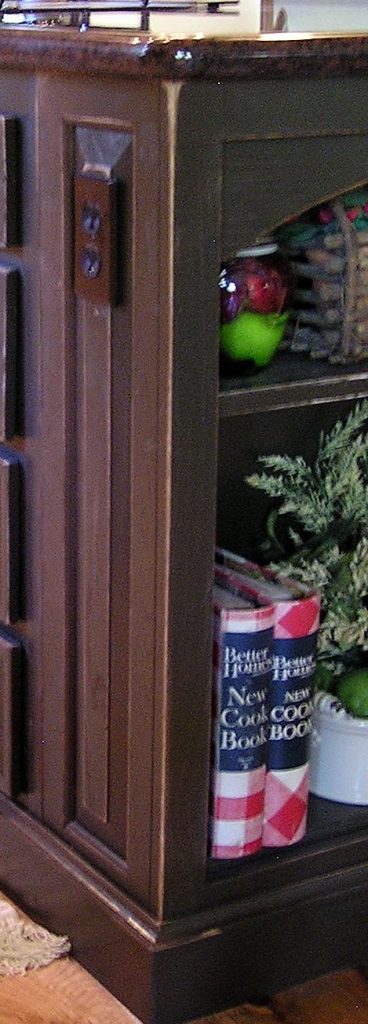

A World Class Designer’s Work

This kitchen tested our shop like no other set

A designer ran into us at a local Home and Garden show and brought one of his clients, a very wealthy class action lawyer down to hire us to do the cabinets in his new home out in Shawnee. This set was way past $50,000.00, one of those “if you have to ask you can’t afford it” kitchens. At one point they had given us the specs for a $10,000.00 copper

.

sink but changed it for a stainless steel sink later on in the job.

The fireplace is actually red, dark barnyard red, but the camera lense picked it up as orange somehow. Those arched doors and crown on the flanking bookcases are actually the same shape on top as the doors, not an easy thing to accomplish but thankfully it was paint grade where bondo is your best friend.

The designer had some great ideas including doubling up on the corbels and island posts. The granite was Delicutus, basically held together by polyester resin and fiberglass backing. You can crumble this stone using your bare hands so the double corbels were good insurance and looked neat as heck.

The end panels were all raised paneled, custom made to fit each junction between upper and tall cabinet sets. Basically a ten foot tall x two foot wide door made out of two dozen rails, stiles, and raised panels. Normally you would use plain plywood on these cluttered end panels and they wouldn’t look out of place but the sky was the limit on the budget on this job. There is light railing on the bottom of all the upper cabinets to hide the under cabinet lights.

The uppers had stackers, additional cabinets that allow you to split the doors into two vertical sections. These cabinets are actually inset doors on face frames but you can achieve the same look in European style cabinets. The interior of the upper stackers were lit up individually.

Crown molding on staggered height sets requires a “landing” place, a place for the side section of the crown to “die” into and you have to think about how the door on the next cabinet is going to bump into the crown molding so it doesn’t get beat up with use. Fillers or wide stiles are used to provide these landing spots. All of those crowns were pre made after the cabinets were assembled and pre finished before installation so there are no nail holes and all the crown junctions are sanded smooth and level before finishing.

Another advantage is the ability to remove the crown cap with the attached crown if the cabinets ever need repair or modification. Most cabinet makers nail the crown to the cabinets so you can’t get the crown off without destroying it.

The kitchen has two islands, the black painted cooktop island and a huge bat winged shaped front island that housed the sink and dishwasher. The furniture style toe kick wraps around the side and back side of the raised bar top. Everything including the bar back walls were pre made, pre finished, and assembled on site and you can’t tell that it wasn’t built in one piece.

Their were almost no organizational products used merely because the kitchen was so huge that there was plenty of room to store things without relying on organizational products from Rev A Shelf. There are full pullouts under all of the double door lower cabinets and full pullouts in the pantry cabinet plus that full size walk in pantry in the corner.

The cabinets were made using maple stiles and rails, maple toe kicks, maple raised panels, maple corbels, carvings, and trim, and MDF carcass parts. Even when price is no object the MDF panels make the superior cabinet carcass.

The finish is a simple paint finish using a coat of white under coater, sealed with pre cat sealer, then lightly distressed and sanded through, then sealed again with another coat of pre cat sealer, glazed lightly, and top coated with pre cat lacquer in a sixty sheen finish.

You don’t get to do many of these $50,000.00 kitchens here in Oklahoma so these are pleasures to work on. Designers generally will take their clients to someone like Karen Black where they will look at you when you walk in the front door and tell you that their kitchens start at $100,000.00. Now an interior designer’s commission on that kind of work is a whole lot more than on our work so we were lucky to run into a designer that thought more of his client’s pocket book than his commission on the job.

The designer was great to work with because he would listen to the best way to build the cabinets and work with you to get the look and finish that he was after. I thought the design work he did on the fireplace and bookcases was world class and we had to struggle to accomplish those eyebrow cabinet tops to create his design. When it came to the finish he let us run wild and I think the collaboration made a stunning kitchen in the end.

Cabinets for a house out on Waterloo Road

- A lot of room to stagger heights and depths on this set

- Simple arched vent hood liner cover but elegant

- Set in microwave instead of a built in microwave

- Five part columns to cover bar back joints

- See, even plain end panels will fit in with an old world design as there is a need for places less busy

- The hood is the focal point and the reason why one of these custom hoods are worth a $1,000.00

Almost didn’t get paid on this job. The builder had good intentions and he knew that a trophy kitchen would sell his spec home quicker than the normal junk that the stick builder cabinet makers put out. But he almost bought too much kitchen for his house

This job was memorable because the builder ran out of money and took forever to pay. But he got good cabinets, just didn’t think of the consequences as most builders (not all) aren’t well financed and work on credit from suppliers and sub contractors.

The kitchen is a simple but Old World design made from Maple and MDF. This job was done back when we did a lot of face frame cabinets, before we could afford the equipment for making frameless or European cabinetry.

With European cabinets you save about four inches inside each drawer and door by eliminating the face frame and the blocking for the drawer slides.

On a medium sized kitchen you wind up with about 20% more storage space, even more on a small kitchen where the individual cabinets are smaller and the finished space even more precious. Smart cabinet makers don’t borrow money because the industry is cyclic and you have to be prepared to hunker down when recession hits and survive. Hard to do that if you borrowed money for your machinery so we waited till we earned enough to invest in the equipment needed to make European style cabinets, buying it at auctions from the dumb cabinet makers that knew a banker.

The finish is a paint finish using a coat of white under coater, then sealed with another coat of pre cat sealer, glazed lightly, and top coated with pre cat lacquer in a matte finish.

Cabinets like this need to be shop made, not built on site. Stick builders that work on site simply won’t have the equipment or experience to pull off work like this. If you are in the Oklahoma City area and need a master cabinetmaker give us a call and we will a nice kitchen almost anywhere in the state of Oklahoma.