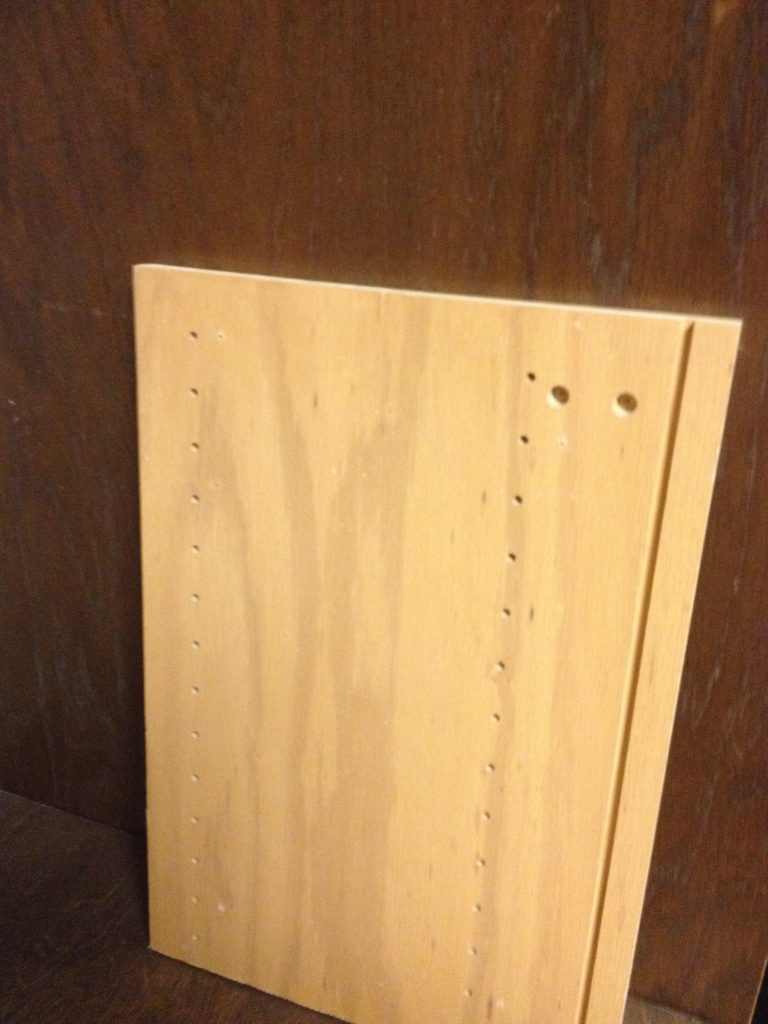

It all starts with System Holes

Always in the right place, always accurate

European cabinet designs came out of the aftermath of WWII when millions of homes and businesses needed to be rebuilt from scratch due to the ravages of war. Many of the skilled craftsmen and laborers were dead and there was so much to do that there simply wasn’t time to do things the old way. People were financially ruined so anything made would need to be a great value.

Rather than make hand made cabinets with all the inaccuracies and inefficiencies a modular system was devised where all the hinges, drawer slides, and shelf brackets inserted into a series of holes drilled in the sides of the cabinets, system holes spaced 32 mm apart, about 1.25″. The speed of assembly was much quicker and more accurate. No measuring, no fitting, make a door or drawer and it fit. The hinges and drawer slides evolved to be quickly inserted into these system holes and to provide small adjustments if needed.

The neatest thing about European Style cabinets is all the really cool hardware that can be used. First here are the hardware items that you won’t see but are so important for installation and longevity

- Adjustable legs/levelers

- Slotted steel hanging rail

- Upper cabinet hanging blocks

- System holes

- Really cool cabinet organizers in the section below

No blocking or fillers were needed inside to install drawer slides, the hinges took seconds to insert and hang, fastening the shelves in place was eliminated and made adjustable to shelves for more efficient storage.

Are there any downsides? Yes, sorta, in that the material used for cabinet carcasses must be without voids so that every hole is in solid material. The only other thing is that cabinet heights and door/drawer heights are fixed in 32mm or 1.25″ increments so that the hardware fasteners will always land in a system hole. However the toe kick height can be adjusted if we need to hit a certain height. And on occasion an exception can be made on door heights if it fixes a problem with layout but it is time consuming to do.

Steel Hang Rails and Cabinet Hanging Blocks

Steel hang rails and cabinet hanging blocks support our upper cabinets. Face frame cabinets use a 3/4″ x 2″ hang strip in the back of the cabinet and I have seen cases where the cabinets have collapsed, leaving the cabinet back and hang strip still hanging on the wall

Then you always have some ugly screw holes showing, usually scraped areas where the chuck on the drill or power screwdriver rubbed the cabinet top as the holes were drilled or the screws were driven. Then the holes and screws have to go at an upward angle so that shoves the cabinets up a bit, making the bottom edges of the adjoining cabinet not line up perfectly. And two men are required to hang, one groaning and complaining while holding the cabinet in place while the other drills enough holes till he finds a wall stud to drive a screw.

With our modern hanging system the slotted steel rail is screwed to the wall studs using tough deck screws. The hanging blocks are installed into pre-drilled holes in the side of the cabinet end panel so the entire end panel is carrying the weight of the cabinet and contents of the cabinet. Then the cabinets are simply hung on the steel rail and slid down into position.

A long Phillips screwdriver is used to adjust an adjusting screw that takes the cabinet up and down till the bottom of the adjoining cabinets line up, and another adjusting screw is used to move the top of the cabinet in and out till the front faces of the cabinets are aligned and everything is level across the front face of the cabinets. Then the cabinet is leveled across the back til it is perfectly level.

If the cabinet ever needs repaired the side fasteners are removed and the cabinet simply lifts off the hooks so the cabinet can be modified or repaired.

Each hanging block is capable of supporting 300 pounds, or 600 pounds per cabinet and that is the safe loading amount, not what it will actually support. Then the cabinet is fastened to the other cabinets so if one cabinet is overloaded the cabinets to each side can help support the load safely.

A typical deck screw will hold around 500 pounds in shear, never use drywall screws which are brittle, so as long as you hit all the studs with a deck screw and any end section that doesn’t have a deck screw within 2″ of the end of the cabinet gets a big toggle bolt the cabinets are very, very, well secured.

We do recommend that on jobs where the drywall is being replaced, that blocking be inserted all across the areas where upper cabinets are to be installed. That gives great support and eliminates any need to rely on toggle bolts.

Where very heavy cabinets are right up next to a window or door trim it is a good idea to cut out the sheet rock in that area and add a single block between the studs because the end screws won’t be able to reach a stud. The cabinet will cover up most of the repaired sheet rock. This isn’t usually needed unless there is something like a huge, deep microwave cabinet or an unusually wide upper cabinet. The only down side to using this hanging system is that a 3/4″ cavity is left behind the cabinet back to allow for the hooks on the hang block and the steel hang rail. This is actually good as it forces the cabinet maker to plant the cabinet back in a groove or dado which gives good support for the back and if you have a crooked wall you can shave down the back of the bottom of the cabinets to keep things lined up despite the crooked walls . As one of Oklahoma City’s best cabinet maker we know that good hardware is the foundation for a cabinet as it makes it easy and efficient to build, easy to install, easy to adjust years after installation is done, and easy to repair or replace parts if needed without destroying the cabinets or the finish.

Adjustable Legs/Levelers

The smaller part is a socket that is inserted into holes drilled in the bottom of the cabinet. A two part leg serves several purposes. First to make sure you can get the cabinet through a standard 36″ front door. A Euro cabinet base cabinet is 30.5″ tall before the legs and toe kick bring the height to 34.5″ tall. Face frame style cabinets have attached bases so the cabinets are already 34.5″ tall which will not go through a standard 36″ wide front door if the cabinet is shallower than around 33″ so you can bring the cabinet in sideways. Where that will bite you is on the corner cabinets which are usually 36″wide x 36″ deep. Using these legs and sockets keep the toe kick off the cabinet until it is installed, making it possible to get a corner cabinet through a standard doorway.

Second, the socket makes assembly easier and protects the bottom of the cabinet during assembly, finishing, transport, and installation. The socket projects down about an inch, lifting the bottom of the cabinet off the work bench top to avoid snagging or scratching the bottom edges. Then in finishing it keeps the bottom up enough that you get a good finish on that lower edge. During transport and installation it keeps the finished bottom edge off the floor of the trailer and allows you to just slide the cabinet around safely.

During installation the long leg portion is inserted into the socket and tapped down tightly using a hammer. A laser has already been used to determine the level of the floor so the cabinets are installed starting at a high point and the legs can be screwed in or out to accommodate the out of level floor. This makes for fast, accurate installation and very level cabinets. Years later the toe kick can be snapped off in most cases for spraying for bugs, for re leveling the cabinets if the house foundation settled, or for running electric or water lines.

Another great feature is if you have an air vent coming out from under the cabinets. Always leave the vent open to heat or cool the underside of the cabinets, especially areas that have a sink or dishwasher. Why? Mold and bugs, neither can survive without a source of water, so allowing the heat and air system to pressurize the underside of the cabinets keeps things nice and dry. The only down side is that it takes a few seconds for that cool or heated air to begin coming out of the vent, something that you won’t even notice.

These legs will support around 300 pounds each, times four or more per cabinet, minimum 1200 pounds capacity, plus the back stretcher of the cabinet is screwed to the wall studs and the installed toe kick will carry some of the load.

But the best reason for using these legs is that the cabinet is sitting 4″ above the floor so a broken water line or drain line from the fridge, sink, dishwasher or even the washing machine won’t ruin the cabinets. The toe kick and maybe an end panel might need replacing if it soaks for hours but the cabinets will be fine. Around 2% of all cabinet installs are ruined by someone forgetting to tighten a water connection.

We had one customer out in Edmond that had a prep sink copper water line break after seven years and the water ran all night until they discovered it around 4 am. All the flooring and base boards were ruined but her cabinets only needed the toe kicks replaced and the two doors that had been sprayed with hundreds of gallons of water for hours on end. They could have been stripped and re used but the cost to replace them was low enough that we didn’t want any absorbed water causing finish problems down the road.

Another huge benefit of using these legs is if something happens to one of the cabinets. Lets imagine that another water leak occurred but it was a slow leak that was present for weeks and months and the water eventually got past the pre-cat finish and swelled up the bottom of the cabinet. MDF won’t disintegrate like particle board but it will swell up if soaked long enough. Remove the water and it will shrink back down to almost the original size but as the cabinet bottoms are made to be replaced, it is a simple matter of lowering the cabinet legs enough to allow the cabinet to be pulled out, taken to the shop, and a new bottom installed and finished. Or if someone wanted to change a cabinet or add a second dishwasher or trash pullout or bank of drawers. You can remove the cabinet without damaging the other cabinets.

The crown molding is glued and pinned to a plywood cap that fits the cabinet just right, the only limit to the size is hauling the completed crown cap. Since all the nailing and sanding is done prior to finishing the crown looks nearly seamless and neat. The entire crown cap lifts off after you take a few screws out. Normal cabinets have the crown nailed in place.

Now you know how a real cabinet maker thinks about cabinets. What goes inside and what supports the cabinet is as important as the exterior looks and style. If you need cabinets in Oklahoma please give us a call.

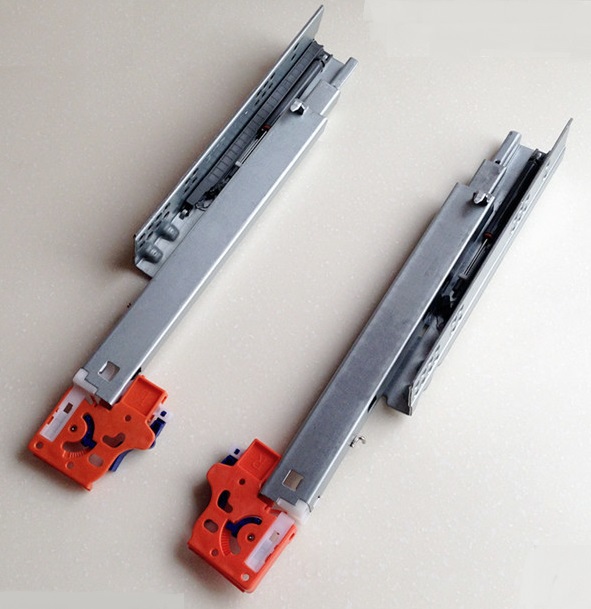

Drawer Slides, from $2.00 to $65.00

Drawer slides are available in many styles and price ranges. the most common is the second picture from the top picture, epoxy coated euro slides, used with wood or plywood drawer boxes, the cheapest out there. One of the drawer members will be “captive” or have a hook that makes sure that side won’t fall off too often if the slide bends. They are usually used with plastic brackets that allow quicker installations but also allow the slide to bend and the drawers to fall off. The advantage is that they are cheap and with the single captive member if you get close they will work okay. There is no adjustment possible for the drawer front other than moving the front around manually. The price of these slides is included in our cabinet quotes but we prefer the better quality Zargen system to the left if you are on a laptop or desktop computer.

Next in line, #1 ar the top, are side mount ball bearing slides. These are usually used with plastic brackets to speed installation, but we won’t use and don’t need to use them as Euro cabinets have flat side panels so the slides attach very solidly to the side of the cabinet. The #2 picture is the soft close version and they are not very durable, I’ve had them break during installation, very fragile. The ball bearings eventually begin to fall out so the life span will be between five and ten years before they will need replaced. The side mount ball bearing slides are $10.00 per drawer, $15.00 for the soft close version.

Next in line is #3 from the top, with the orange tips. Those are undermount slides that use 5/8″ wood drawer sides and backs, 3/16″ bottom in a 1/4″ dado. They are soft close, have excellent adjustment of the drawer front, up, down, and side to side. The orange parts are the front clips used to disengage the drawer from the slides. Very good quality, long lasting, and heavy duty, $30.00 per drawer extra cost.

The picture to the right is the Nova Pro slide system. It is an undermount slide like the one above with a very nice metal drawer side system. They are soft close, the front will snap right off for cleaning and snap back in place with only a little tool free adjustment side to side using your fingers, and they are top quality slides and should be for the $65.00 per drawer cost. Like the Zargen drawer system we need only make the back and drawer bottom. These actually cost us $65.00 per set but the savings from not making a full drawer box pays for the installation.

The picture to the right is the Nova Pro slide system. It is an undermount slide like the one above with a very nice metal drawer side system. They are soft close, the front will snap right off for cleaning and snap back in place with only a little tool free adjustment side to side using your fingers, and they are top quality slides and should be for the $65.00 per drawer cost. Like the Zargen drawer system we need only make the back and drawer bottom. These actually cost us $65.00 per set but the savings from not making a full drawer box pays for the installation.

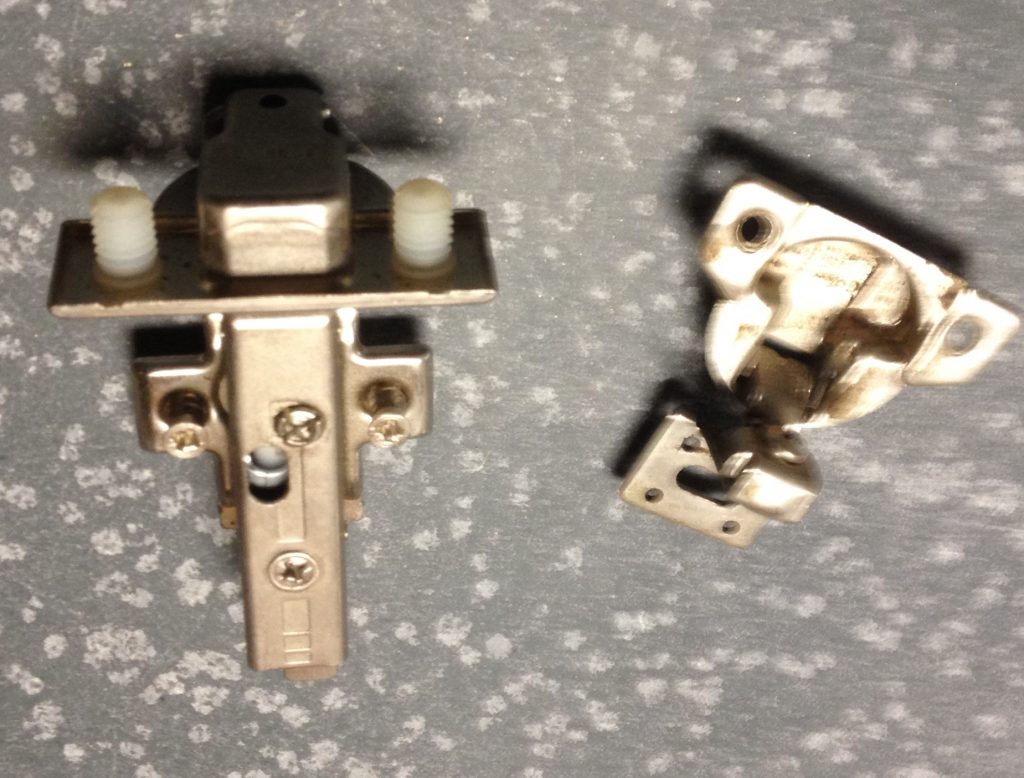

Most cabinet makers are going to use the small hinge on the left, the “tech” hinge simply because they are cheap, around 35 cents per pair bought in quantity. They have very limited adjustment, usually up and down an 1/8″ or so, and a single screw attaches the one piece hinge to the cabinet face frame. The adjustment is done by loosening a screw, pushing the hinge over, and tightening the screw.

The larger hinge one the far left is the clip on hinge with a separate base. Twice the adjustment, mostly cam based where you don’t loosen or tighten a screw, just turn it to move the door back and forth or up and down. The in and out adjustment is usually done by loosening and tightening a screw though. The hinge will unsnap, allowing the door to be removed and will snap right back in place without adjustment required. Super handy for installing shelf paper, cleaning, or when a big butt plumber is working.

The separate base plate can be the face frame style for odd sized doors where it is tough to hit the system holes or for standard height doors you can use the wing base plates that hit two of the 5mm diameter system holes.

The face frame versions do use two screws but they are normal hinge screws, usually #6 x 3/4″, easy to snap off as they can be brittle. But the wing plates or Euro plates use 5mm screws, around five or six times thicker. In engineering when you double the thickness of something you don’t double the strength, you quadruple the strength, so a 5 mm screw will carry a dozen times more weight and stress than a typical hinge screw.

European Hidden Hinges

- Out of sight

- Six way adjustable

- Soft close options available

- Unsnap the door if needed, goes right back on without adjustment afterward

The doors are drilled with one standard setting, 3″ down, and the two nylon inserts are pressed into the 5 mm holes. No drilling, no screwdriver needed, when the 32 mm hinge cup hole is drilled the two 8 mm holes for the 5 mm screw nylon inserts are drilled too in perfect placement. Then you flip an arm down, snap the hinge on the arm, and press the hinge into the door. The end result is to hang a door ten times faster than using a face frame tech hinge so you save money on labor and have a much, much, stronger screw attaching the hinge.

A soft close option can be accomplished in several ways. First is an add on cylinder, one screw secures the cylinder up in the top corner and these can be bought for around $4.00 and installed by the homeowner. They are plastic though, not going to last for very long. Then there is the $8.00snap on soft close like on the Grass hinge where the metal cap holds the plastic piston in a metal cylinder and the entire assembly just snaps on the hinge cup end. Or you can pay for the dedicated soft close hinge like on the left in the picture. The down side to those is that if the soft close breaks the entire hinge must be replaced and there is less adjustment in the hinge.

MDF on top, Particle board on bottom

Not even close to the same material

Particle board was designed as under layment for the old solid wood sub floors, the 1 x 6 or 1 x 8 plank flooring. In that use it had some value if it didn’t get wet but somewhere along the line some cheap SOB decided it could be used for furniture and cabinets. The center is coarse sawdust, the outer layers are fine sawdust, glued together with formaldehyde glue. Most cabinetmakers hate it.

MDF starts off as long stringy fibers piled in a mat that is about 6″ thick, then heat and pressure press it down to 3/4″ thick so the interior is very dense and void free.

Carcass materials

- MDF is hands down the best material for Euro cabinets

- If you just have money to waste there is a plywood hybrid that is usable

- Use the right material in the right place

- Hardwood stretchers are a must

But MDF has its limitations and is best used for shelves, end panels, raised panels, Zargen drawer bottoms, decks and tops, any part that is mostly face nailed or face screwed.

Lower cabinets use 3.5″ rails or spreaders made out of hardwood because MDF would simply split in such a narrow part. Yet the top of an upper cabinet will do just fine with MDF because it is a foot wide as long as you keep the large screws back from the edge and rely on glue and 16 gauge brads to secure the very ends. We use special screws that have a type 17 drill point and very coarse threads and at the top end it has nibs that clear out some material so the screw pulls down flat. Keeping in mind that a cabinet might need repair in the future you want to put things together solidly yet not make something that can’t be disassembled.

MDF would make a terrible drawer side too because it would split in such narrow widths as the drawer fasteners went in. Maple hardwood is much better for drawer sides.

Toe kicks are another place where MDF wouldn’t work well because a toe kick is going to have to stand up to being mopped a lot so hardwood must be used.

End panels are best done using a wood veneered MDF sheet so that the paint matches. Not so for the raised panels on paint grade sets as shapering the raised panel would chip the wood veneer and on a door you have a lot of detail going on that distracts they eye, unlike a big flat fridge end panel that needs some grain to match the door rails and crown molding. Painted raised panels are great in MDF, it shapers smoothly, lays nice and flat unlike a real wood raised panel, and MDF is so stable that the raised panels don’t shrink and swell and leave a white line around the perimeter. Back panels can be plain veneer covered MDF panels if there are bar stools hiding most of the back side or a five part or raised panel back panel. For five part doors the best inner panel is MDF double side wood veneer sheets.

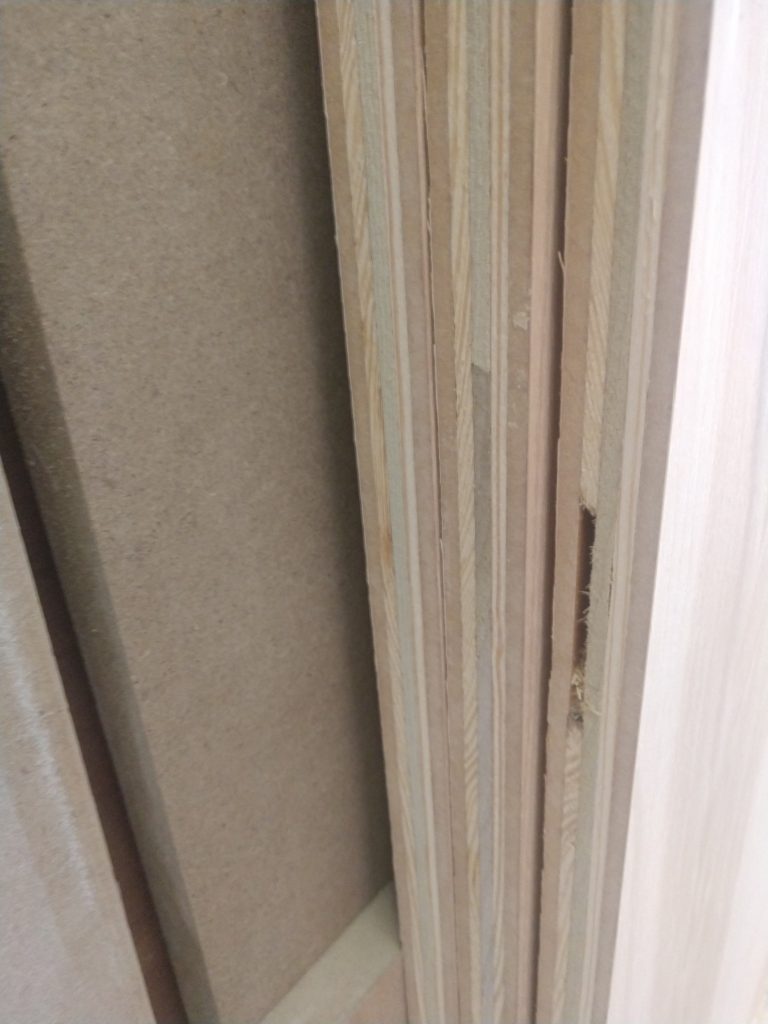

End Panels are a source of gaps in most face frame cabinets like in the picture below of the stained cabinet with the fluted corners. We plant end panels on the side of the cabinet so that any door or drawer front gap gets covered up by the end panel. This requires us to work with more precision but the cabinets look a lot better in the end. Medium Density Fiber board or MDF is the best choice of carcass material hands down. Compared to plywood it is much heavier but that is the only down side. It is stiffer, flatter, more uniform thickness within the sheet and sheet to sheet, won’t fall apart like plywood and particle board does when it gets wet.

in most face frame cabinets like in the picture below of the stained cabinet with the fluted corners. We plant end panels on the side of the cabinet so that any door or drawer front gap gets covered up by the end panel. This requires us to work with more precision but the cabinets look a lot better in the end. Medium Density Fiber board or MDF is the best choice of carcass material hands down. Compared to plywood it is much heavier but that is the only down side. It is stiffer, flatter, more uniform thickness within the sheet and sheet to sheet, won’t fall apart like plywood and particle board does when it gets wet.

Plywood’s largest problems are the voids inside the core, the warping, and the uneven thickness within a sheet.

With the System holes there needs to be solid materials for the 5 mm hardware screws and shelf pins to fit into. There are way too many voids in regular plywood. You might not find the void until you are assembling the cabinets and hanging the hardware and a screw strips out so you have to re make the part and re finish it.

And plywood warps like mad, even the 3/4″ sheets, and without a face frame to hold it in place the sides of the cabinet bow in and out. The side margins on Euro cabinets are only 3/16″ so even a small bow shows up like a sore thumb. Back in the day the core material of plywood was much better cured and dried and they could use some pretty harsh glues but these days the competition overseas has driven the plywood makers to a race for the bottom and the good chemicals have been removed from the glues by the EPA or California.

Plywood is notorious for being uneven in thickness from one end of the sheet to the other and from sheet to sheet. With the super tight margins on Euro cabinets you just never know how a line of cabinets is going to measure across the

top or bottom due to varying thicknesses so the cabinets aren’t as square. Sometimes the inaccuracies cancel out, sometimes it adds up and creates problems.

There is a hybrid plywood called Classic Core made over in Arkansas. It has a plywood inner core, two layers of MDF on the back and front that allow it to be calibrated for thickness before the outer veneer is applied. It isn’t cheap, figure around $450 to $500 on a small kitchen and twice that on a larger kitchen. If there are voids you have the MDF layers so you are at least catching some good material with the hardware screws. It stays pretty flat too. All that said, if the cabinets were going in my home, I’d save that money and buy nicer appliances or really nice knobs and pulls. Plywood is wonderful to work with, about 75% of the weight and your back sure knows it at the end of the day when handling MDF sheets but we have done $1,000.00 per linear foot cabinet jobs, even $2,000.00 a foot cabinet jobs and the MDF was always our choice of materials for carcasses.